What process does HP Jet Fusion 5210 use?

Our 3D printing process includes multiple stages:

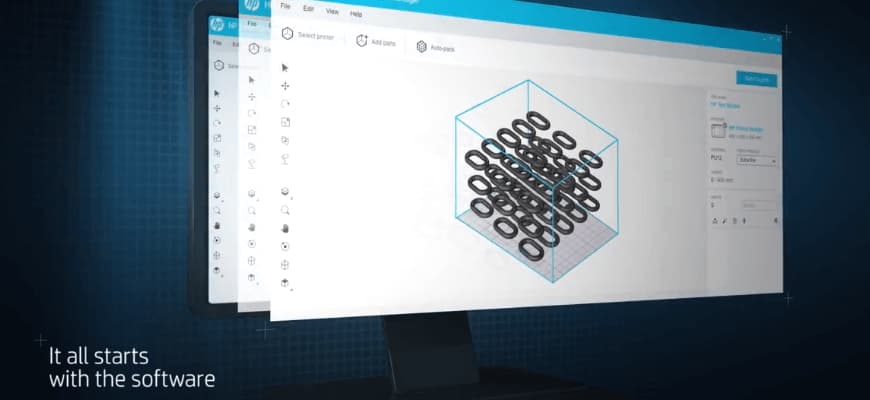

1. Visualization

The 3D model is imported into HP SmartStream 3D Build Manager, an app that creates printer tasks. The space outlined in blue is the HP Jet Fusion 5210’s print volume. Its dimensions are 380 × 284 × 380 mm. Once the details are laid out, the app starts preparing the print task.

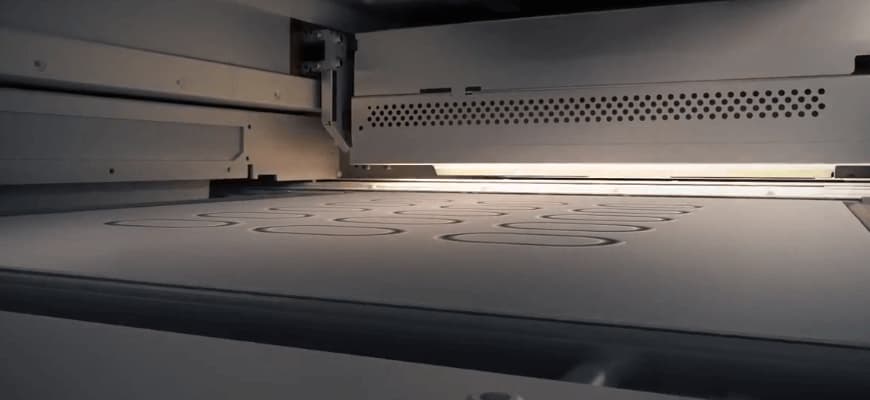

2. Printer preparation

The build unit is loaded with material and then inserted into the printer. Once this is done, it is ready for launch. Your items will be printed from this polyamide.

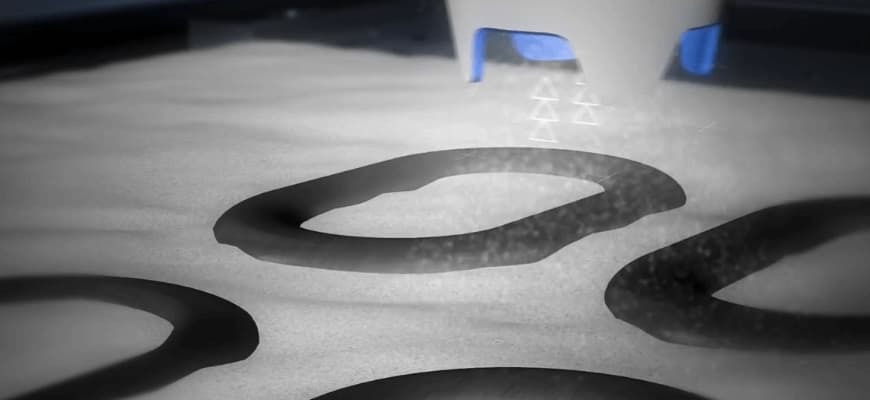

3. Printing

The printer applies a layer of powder and bonding agent, which is then fused under IR light. Once the layer is fused, the printing head applies another one. With Hewlett Packard’s solution, a whole layer is fused in one pass.

4. Cooldown

The build should be cooled gradually to preserve the item’s structural properties and prevent the material from becoming brittle. Usually, it takes up to 12 hours for a build to cool down. Meanwhile, the HP Jet Fusion 5210 can print another one. The printer also has active cooling capabilities: the build can be cooled in just 4 hours, but there is no guarantee the material will be as durable.

5. Clean-up

Multi Jet Fusion is a powder printing technology, so the newly built items need to be cleaned from surplus polyamide. All this is done in the post-processing unit.

Once cleaned, the items are ready for use without additional finishing. They can also be dyed black or gray if need be. Then we send them to the customer.