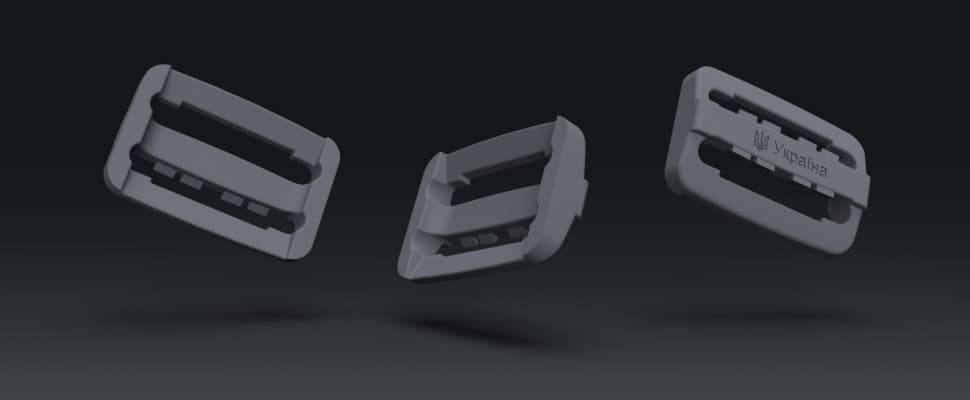

Parts of the tourniquet

-

Client:

an individual

-

Model:

tourniquet parts

-

Weight:

35 g

Volunteers needed parts for a tourniquet made from durable material. Unfortunately, mass-produced items by little-known brands often don’t meet the promised technical specifications. Furthermore, it’s risky to buy things like that, given the scope of use. Therefore, the client decided to have the product custom-made to ensure quality. In this case, two options were available: injection molding and 3D printing.

Injection molding is pricey and takes several months. Consequently, printing seemed the best option. However, the item turned out fragile and couldn’t withstand the required load of up to 70 kg when FDM technology was used.

Solution

The customer turned to Infomir 3D Printing for help. The AFU provided their 3D model of the tourniquet parts and ordered printing. The result delivered by the Infomir was durable, moisture-proof, UV-resistant, and sturdy. Finally, the components were sandblasted and delivered by a postal service Nova Poshta. It took a total of just five days to solve the client’s problem.

Result

The client received durable and customized parts quickly. The item works straight out of the box and needs no additional processing. Thanks to Multi Jet Fusion printing technology and HP PA 12 material specifications, the tourniquet parts can be used in all weather conditions.