Surgical retractors

-

Client’s website:

-

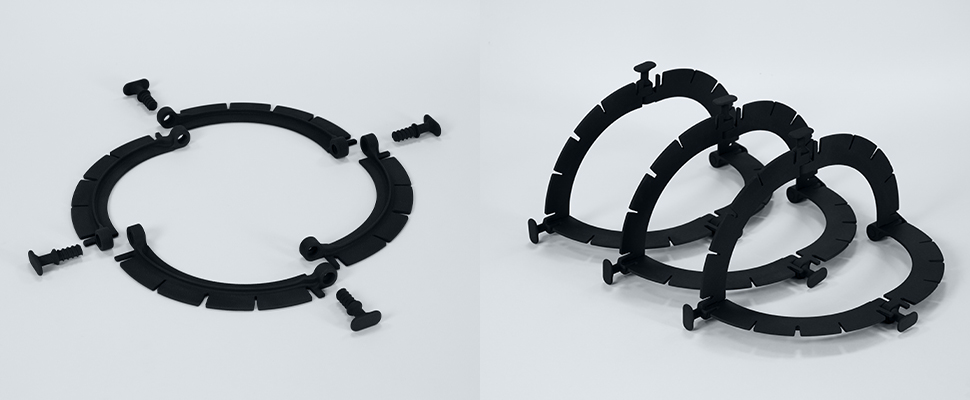

Model:

surgical retractors

-

Weight:

93 g

-

Dimensions:

138 x 138 x 17.5 mm

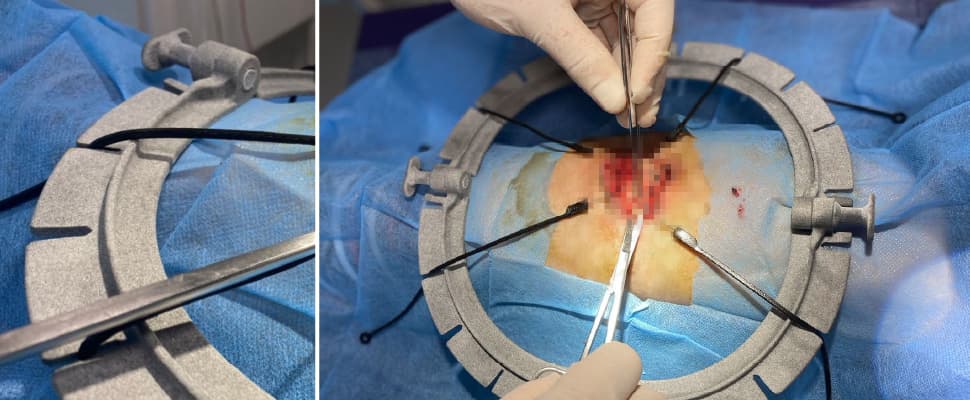

Client’s problem

At the military hospital, the medical staff needed retractors to perform surgeries. However, during wartime, medical institutions have difficulty ordering foreign-made tools due to transportation problems. Moreover, foreign-made retractors would cost the client much more than domestic ones.

The hospital staff opted for getting their tools made using 3D printing technology. The staff tested several technologies, but the quality of the items didn’t meet their needs.

Solution

Backed by a 3D model, Infomir’s 3D Printing experts printed, sandblasted, and delivered a test set of parts for surgical retractors to the client. After testing the tool, the hospital reported that it fully complied with all its requirements and ordered a large batch of retractors.

Result

The military hospital received a ready-made test version of a surgical retractor within three days. Thanks to the high printing resolution, Infomir 3D Printing met the client’s needs, namely creating items with a deviation of no more than 0.2 mm. The heat-resistant HP PA 12 material means the items can be sterilized and reused.

The hospital can now order a batch of 30 retractors at a bargain price at any time and have them printed in 4–5 days.