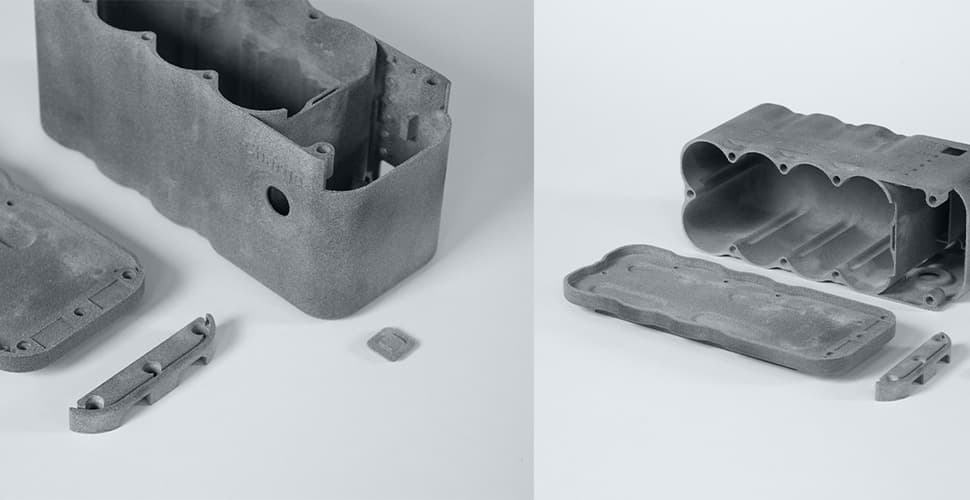

Battery enclosure

-

Client:

-

Model:

Battery enclosure

-

Weight:

80 g

Client’s problem

The company needed a batch of light and durable battery enclosures that could withstand non-critical loads to upgrade its electronic system. In total, 150 had to be produced, with the deviation not exceeding 0.5 mm.

FDM printing didn’t provide the necessary build properties. Die casting molds were unfeasible because of the relatively small batch size and the time it would take to make them as the entire batch had to be produced within a month.

Solution

Kvertus approached Infomir 3D Printing for help and were provided with a 3D model of their enclosure. The order was printed on the industrial HP Jet Fusion 5210 line using the HP PA 12 polyamide powder. Builds of any complexity can be printed with this technology and material, with the resolution reaching 1200 DPI and layer thickness—80 μm.

Result

The client received the finished enclosures within a month. They were durable, light, and resistant to moisture, dust, and UV rays. With the MJF technology, the company saved time and money on producing a one-off batch of enclosures.