Cases for electronics by Droid Technologies

-

Client’s website:

-

Model:

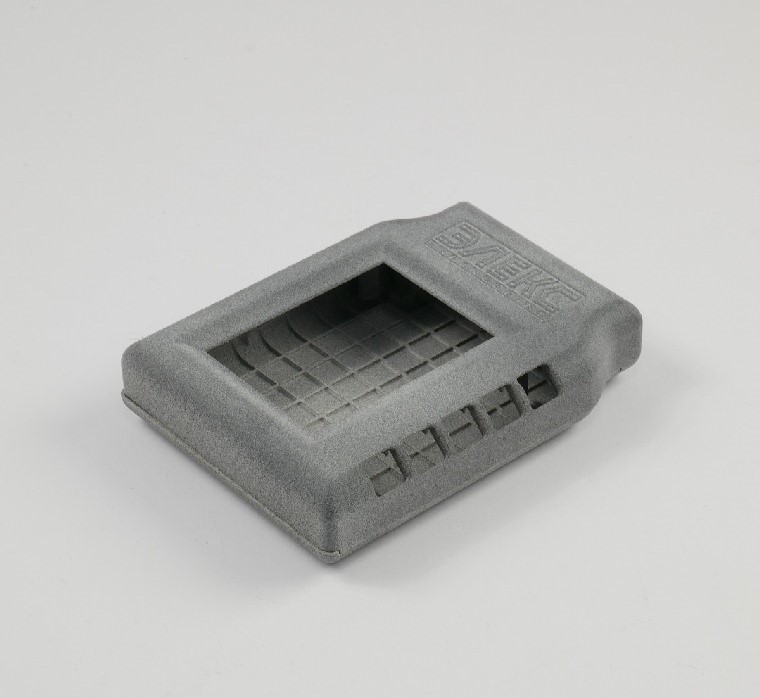

cases for electronics and control panels

-

Weight:

10–1,000 g

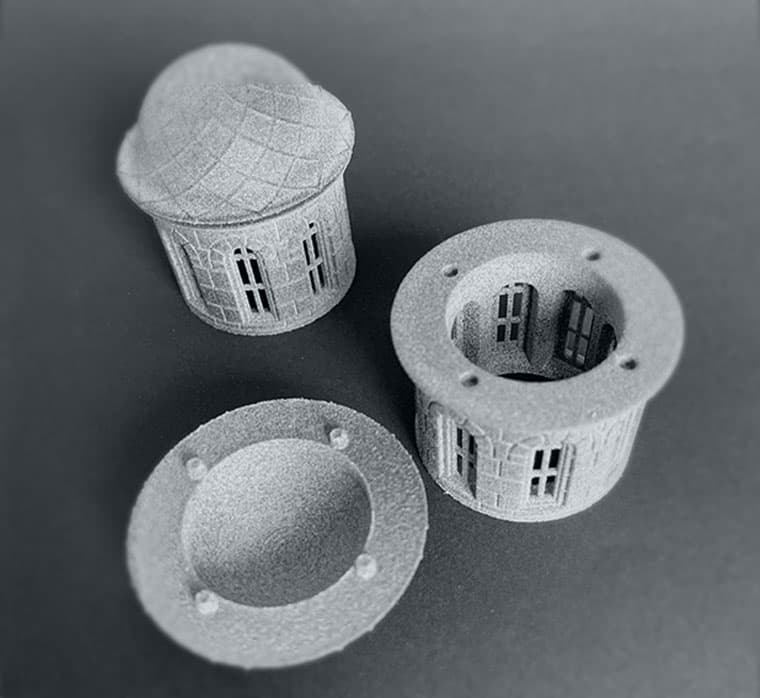

Droid Technologies designs and manufactures electronic devices of different types and sizes for various applications, i.e., traffic and lighting control systems.

Client’s problem

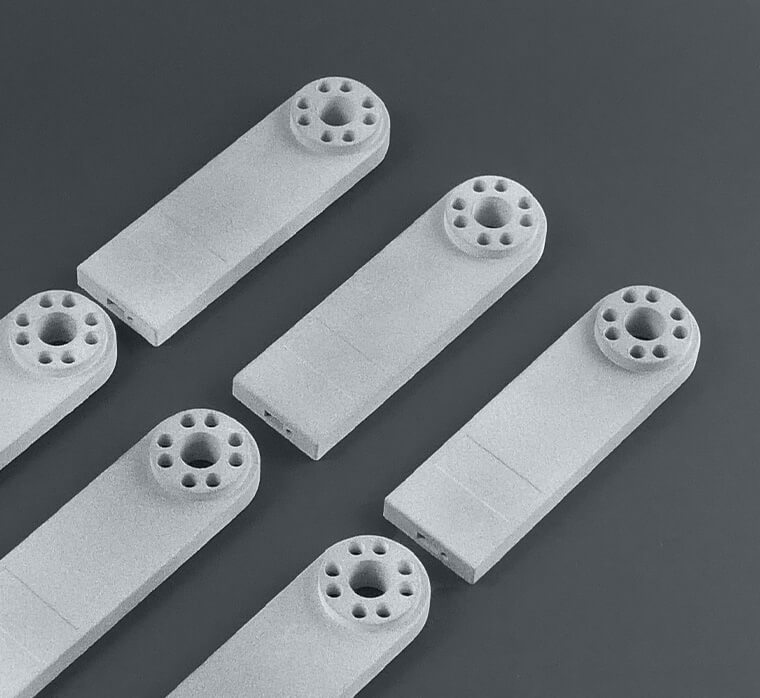

At Droid Technologies, specialists regularly print prototype models of mechanical nodes for electronics. These prototype models are used for quality and feature testing and help find structural flaws before the model is mass-produced.

The company manufactures cases and panels through molding. If the mold is flawed or poorly designed, it’ll affect the entire batch of products. That’s why high precision is a must for prototype models. Apart from that, the products must resist mechanical stress, i.e., falling from human height.

Long time and high costs made manufacturing these parts through molding unviable, while FDM printing couldn’t provide adequate precision and durability.

Solution

Droid Technologies decided to get printing services from Infomir 3D Printing. The parts were printed, sanded, and shipped within 5–6 business days. They were precise and durable, while the qualities of the printing material (HP PA 12 polyamide) allowed the client to drill, saw, and file the parts without cracking or crumbling them.

Result

The client got high-quality prototype models with a high level of repeatability and precision. Thanks to the speed and affordability of MJF printing, the manufacturer can quickly and cost-efficiently react to changes in its orders. Also, Droid Technologies occasionally orders the printing of cases for finished products. It costs much less to use our technology for a limited batch than molding.

Client’s feedback

“The Multi Jet Fusion powder 3D printing technology enables us to manufacture equipment of higher quality in a short time,”

Viacheslav Kahanyuk,

Engineering Designer at Droid Technologies.