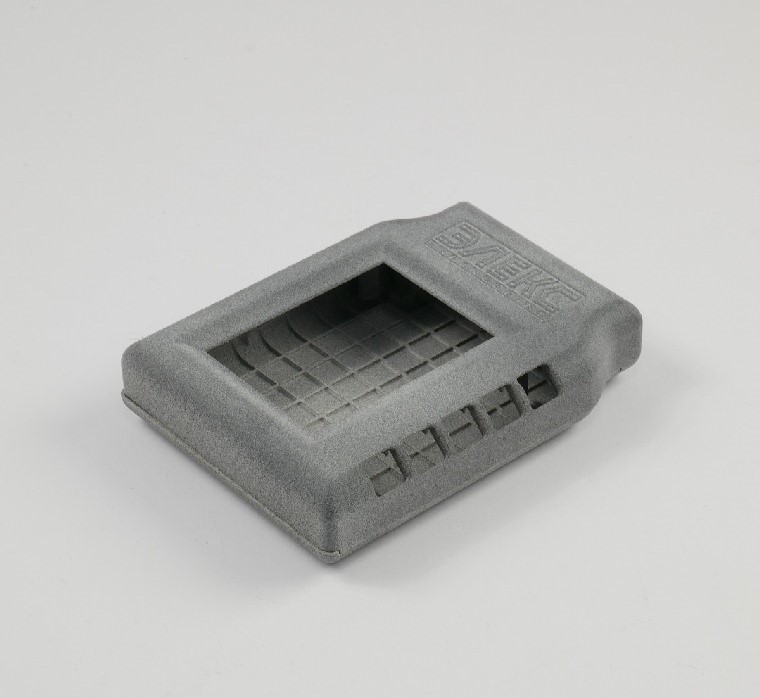

Voltage stabilizer frames for Eleks

-

Client’s website:

-

Model:

voltage stabilizer frames

-

Weight:

150–400 g

Since 2005, Eleks has been manufacturing voltage stabilizers, uninterrupted power supply units, diesel generators, and voltage relays. The company is a facility with full-cycle manufacturing operations, developing and producing equipment in-house.

Eleks also manufactures toroidal transformers, presses plastic faceplates, cuts, bends, and paints frame parts, and casts aluminum cooling radiators. They assemble the small parts using SMD and bigger ones manually.

Client’s problem

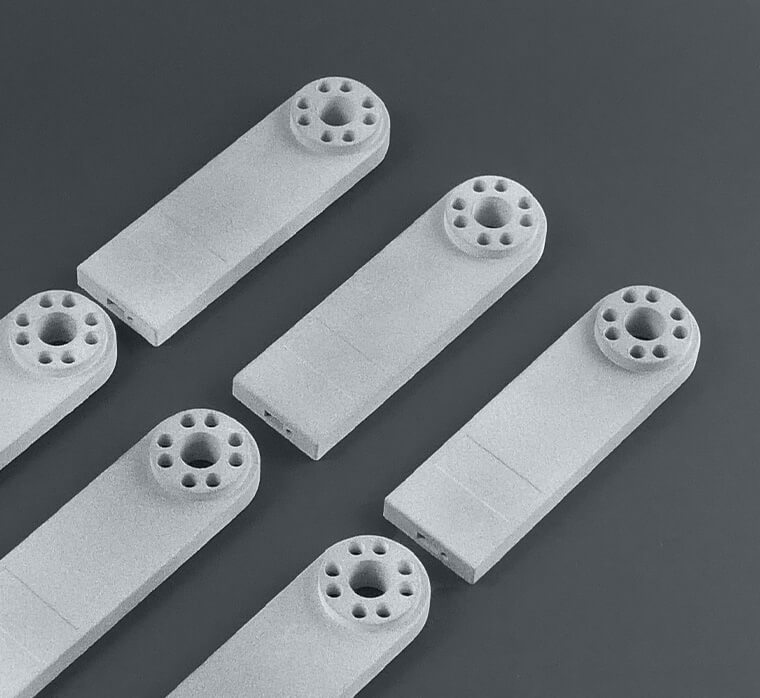

A device prototype must be built and tested in the laboratory before being commercialized. Besides electronic components, Eleks tests frames that must be robust and have all the features offered by finished items.

Conventional plastic molding is extremely expensive. Prior to building prototypes, a metal negative mold for casting must be made. That usually takes several months and costs tens of thousands of dollars. Furthermore, whenever the model needs upgrading, a new mold is required with all the expenses that go with it.

Unfortunately, 3D printing on an FDM printer doesn’t work in this instance, as it doesn’t provide the required durability. Thus, it is better suited to demo samples rather than the items to be tested under real-life conditions.

Solution

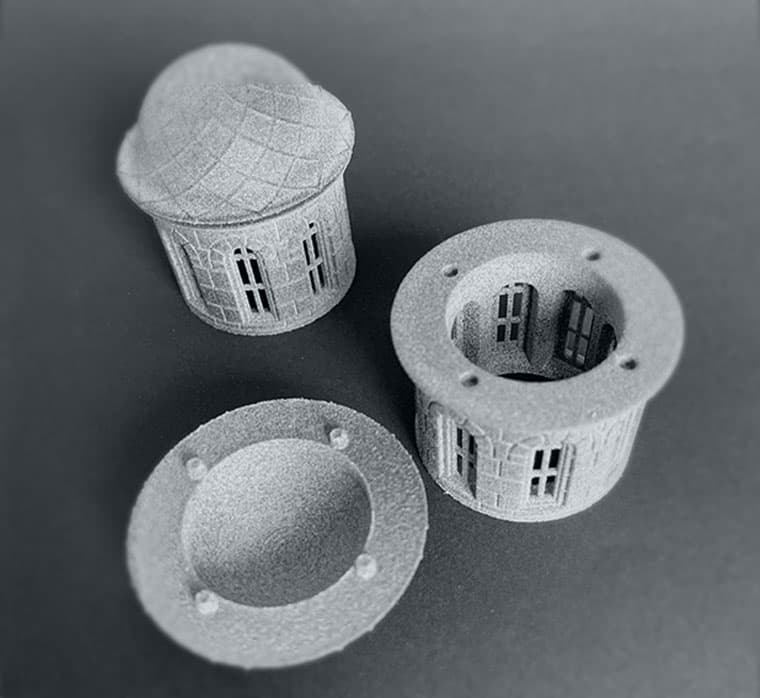

Research and production company, Eleks, requested Infomir 3D Printing to build solid, buildable prototypes. Our HP Jet Fusion 5210 line prints with 80 microns layer thickness at 1,200 DPI. The source material is durable, water-resistant HP PA 12 polyamide, commonly used for car bumpers and dash panels.

We regularly print the prototypes of new items for Eleks, providing them with a 3D model and frame ready for lab tests within a few days.

Result

With Infomir 3D Printing, the Eleks gets frame prototypes with the correct characteristics quickly. As a result, they save months on testing and upgrading new devices, helping them roll out new products faster and showcase functional prototypes at the trade shows.

Client’s feedback

We contacted Infomir 3D Printing as they can create high-quality plastic items that are as robust as cast items. Prototyping technology allows the production of a finished item to start within just a few days, including lab testing. It also helps avoid costly mistakes in the future and significantly reduces product development time. Furthermore, we benefit from the cooperation of Infomir 3D Printing.

Yevgeny Vorobyov,

CEO and Founder of Research and Production Company Eleks