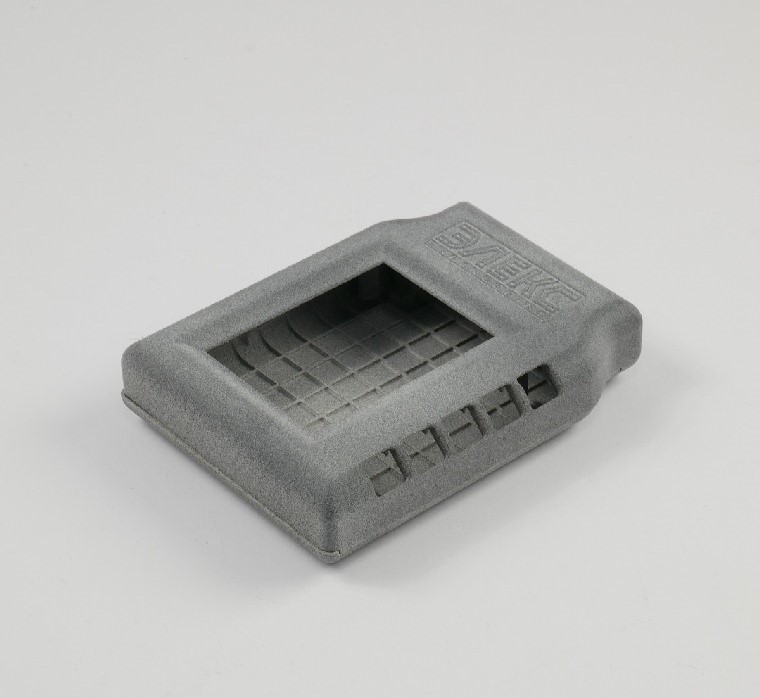

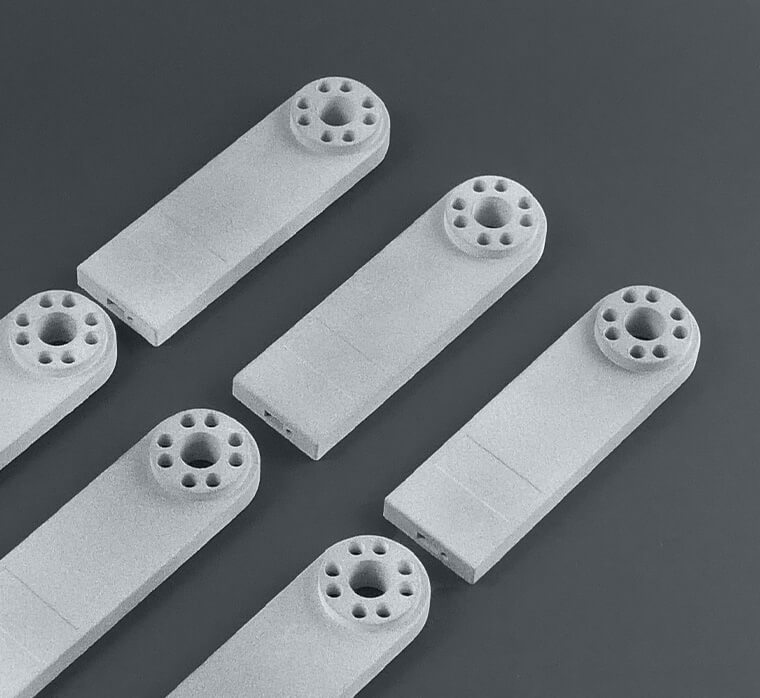

Magnetic sensor housings

-

Customer:

“Alpha-Lift Tech” Ltd

-

Model:

Magnetic sensor housings

-

Weight:

14 pcs each 17 g

“Alpha-Lift Tech” Ltd is an elevator equipment and elevator maintenance company.

Customer’s problem

Alfa-Lift Tech engineers use 3D printing for rapid production of spares and consumable peripherals: the customer needed 14 sets of magnetic sensor housings. The finished products were required to be durable, lightweight and highly detailed. Conventional 3D printing technologies were therefore not up to the task.

Problem solution

The customer turned to Infomir 3D Printing to print a set of parts on the HP Jet Fusion 5210 production line. The products on this printer are created using the MJF method with HP PA 12 material. The finished parts are produced durable and resistant to moisture and UV light. They can be printed at resolutions of up to 1200 DPI and layer thicknesses of up to 80 µ.

The result

A set of 14 magnetic sensor housings were printed within 5 days. All products were exactly according to the customer’s specifications. Thanks to Infomir 3D Printing, the company received high-quality components in a short period of time and at a reasonable price.