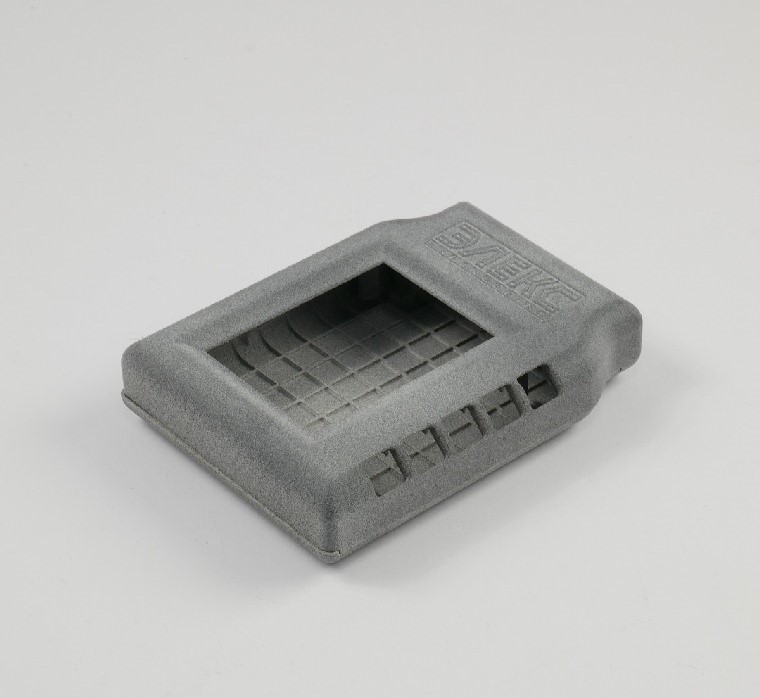

Programmer enclosure

-

Customer:

eleks.com.ua

-

Model:

Programmer enclosure

-

Weight:

5 pcs. each 15 g

Since 2005, Elex has been producing voltage stabilizers, uninterruptible power supplies, diesel power plants, and voltage relays. The company is engaged in full-cycle production: it develops and manufactures equipment on its own.

Elex performs various jobs within their production: they produce toroidal transformers, stamp plastic faceplates, cut, bend and paint enclosure parts, and cast aluminum cooling radiators. Surface SMD assembly is used for small parts, while large parts are assembled by hand.

Customer’s problem

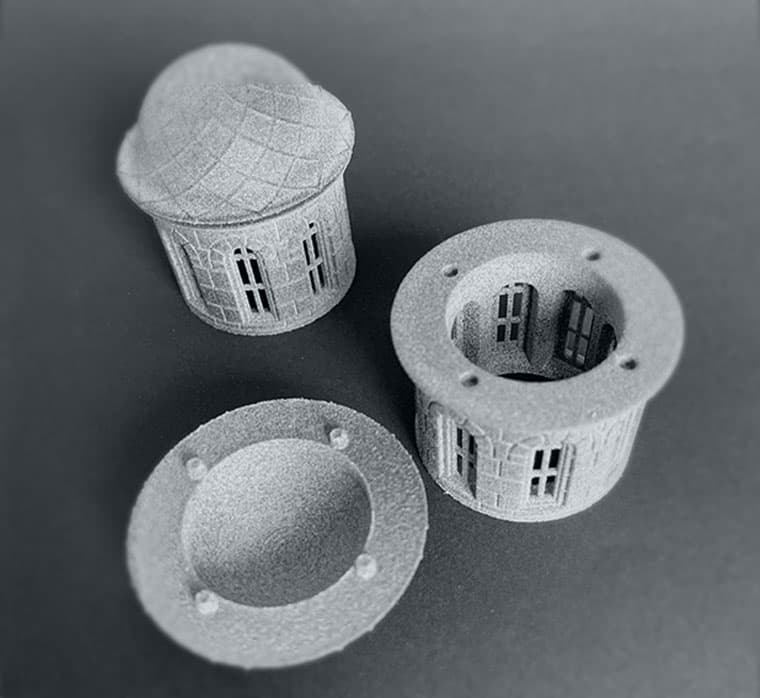

The customer needed parts for programmer enclosures. The products had to be precise and withstand a slight mechanical load. The customer had already used different types of 3D printing to create the parts, but they had not given the required quality and tolerances.

Problem solution

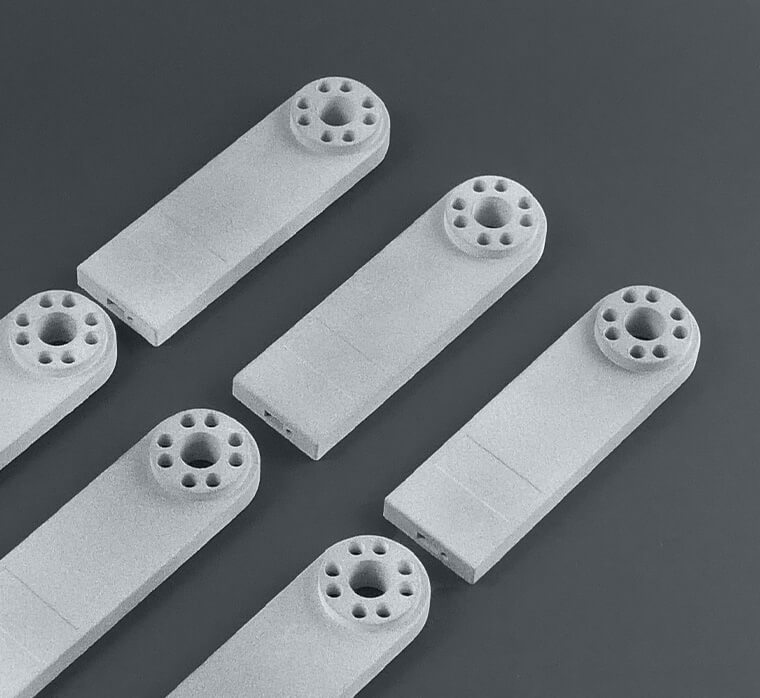

The company’s engineers turned to Infomir 3D Printing for help and provided 3D models of the enclosure parts. The HP Jet Fusion 5210 production line was used to produce them. The parts were printed from PA 12 polyamide. This material and the MJF printing technology allow for durable and accurate printing with high detail — up to 1200 DPI.

Result

The parts for the programmer enclosure were printed and machined within five days. Thanks to Infomir 3D Printing, the company received a complete set of products that met the required specifications and saved time searching for customized parts.