Additive manufacturing: technology, materials, and benefits of 3D printing

Additive manufacturing is a method of constructing an item using its 3D model. Some call this process “growing” because the product is made gradually, layer by layer. Depending on the type of technology, an item is created from the bottom up or from the top down. Today, additive manufacturing is better known as 3D printing. In this article, we tell you more about additive manufacturing, how it works, and why it has become so popular in today’s world.

Why 3D printing is in demand

We can use additive manufacturing to make prototypes, samples, and finished products from various materials, including plastics and composite pieces. Businesses use 3D printing to manufacture industrial, domestic, and medical items. The military industry has also employed this technology. A 3D printer can create car interior parts, aircraft components, implants, and even engine elements. Companies use 3D printing as a visualization tool to quickly test a product to see if it complies with standards. With additive technologies, they can check it before mass production starts.

3D printing plays a significant part in the design field, as companies use it to create uniquely shaped packaging or bottle layouts. Also, you can print design items, electrical appliance prototypes, and furniture. Using 3D prototypes for design purposes enables customers to hold the future project in their hands and study its texture, color combination, and size. They can test whether it fits in with their interior or exterior.

How to print products

Despite seeming rather complex, additive manufacturing takes only a few steps:

| Create a CAD model | To print a product, you need its 3D model. Computer-aided design (CAD) systems help model an object. The most popular software to build a 3D model is Blender, SketchUp, AutoCAD, Maya, 3DS Max, and Inventor. CAD systems save a model in a format that printers can recognize. |

| Upload a model file | You need to upload the finished model file to your printer. After that, the software slices it to create layers and sets the printing algorithm. |

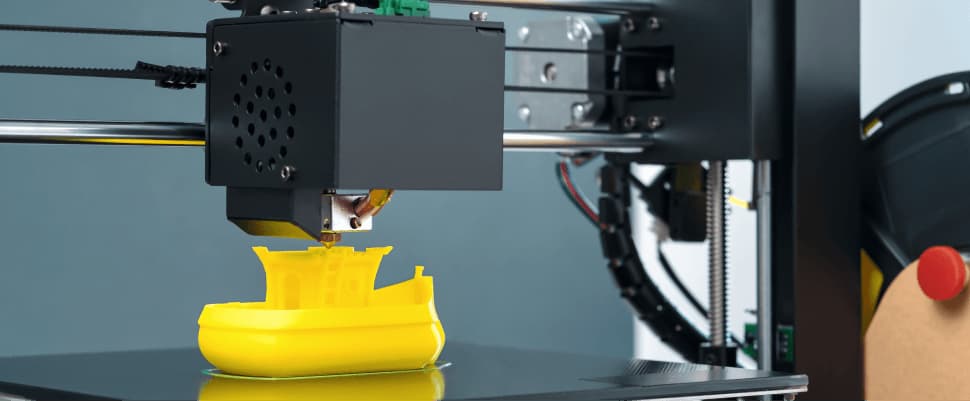

| Printing | The printer creates an object layer by layer until the printing program ends. |

| Cooling | The finished product is removed from the print chamber (bed), and either cooled gradually or using an accelerated method. |

| Post-processing | A finished product is cleaned from the remains of print material, polished, and dyed. This way, you can achieve the optimal texture of an object. |

Types of 3D printingThere are many types of 3D printing: photopolymerization, material extrusion, jet modeling, binder jetting, powder bed fusion, and melting a layer with laser or infrared light. However, the most popular types of printing include the following ones:

- FDM (Fused Deposition Modeling) — each layer is formed using liquid plastic pushed through an extruder.

- SLM/DMP (Selective Laser Melting / Direct Metal Printing) — selective melting of metal powder using a laser.

- SLS (Selective Laser Sintering) — a laser passes over a print bed covered with powder and selectively sinters it.

- MJP (MultiJet Printing) — multi-jet printing using wax or photopolymers.

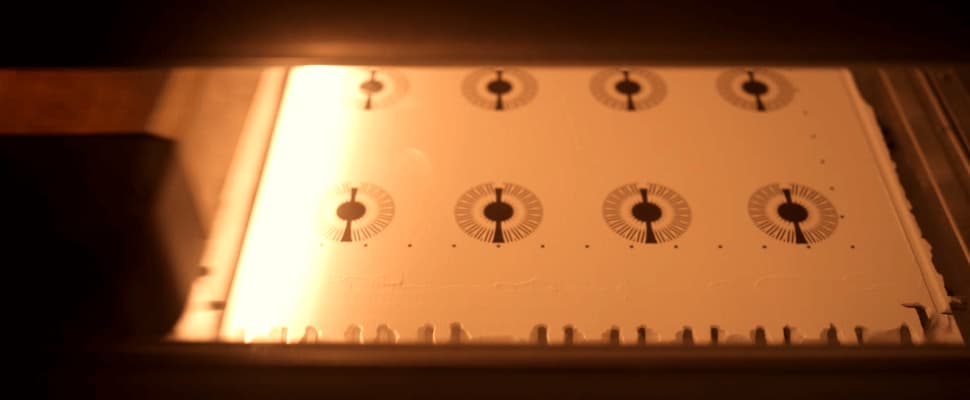

- MJF (Multi Jet Fusion) — polyamide 3D printing where a heating element covers the entire print bed (Infomir uses this technology).

- SLA (Laser Stereolithography) — there is a bath with liquid photopolymer inside a 3D printer. A laser beam passes over the surface of the material, and where it touches the liquid, the photopolymer hardens, creating a layer of a product.

- CJP (ColorJet Printing) — color 3D printing using gypsum bonding.

Printing materials

Melted plastic or metal powder is not suitable as a printing material for every product. However, various other materials may be used as additives during manufacture: gypsum, wax, paper, and composite materials, such as a mixture of polymer and wood chips. We will share what materials you can use for printing. The most commonly used plastic for printing is polylactic acid (PLA). You can get it from renewable resources, such as cornstarch. The material does not release harmful substances, can be used for food packaging, and does not have an unpleasant smell during the printing process.

Printing using acrylonitrile-butadiene-styrene copolymer or ABS plastic is popular as well. The material is suitable for printing matte products. The substance does not release odor and is resistant to high temperatures, fats, and oils.

The melted plastic takes a long time to cool, so 3D models with overhanging elements can be unstable when printed. Support elements are needed during printing to prevent product deformation. Those are often printed using high-impact polystyrene (HIPS). When the part has cooled, it is cleaned with limonene, a liquid hydrocarbon that dissolves the HIPS but leaves the ABS plastic fully intact. It enables you to print intricate products and dispose of unnecessary auxiliary elements quickly.

Among other types of 3D printing materials, the following are popular:

- Polyamide powders (including glass-, carbon-, and metal-filled)

- Metal powder alloys

- Gypsum powder

- Liquid ceramic-filled photopolymers

- Polystyrene powder

- Wax, composite materials, or paper

Benefits of additive manufacturing

About 5–10 years ago, 3D printing was prohibitively expensive. As a result, only large businesses used to print items in laboratories and at exhibitions. Today, we use additive technologies in all fields of human activity. Small startups and large corporations employ additive manufacturing to create various parts, prototypes, and finished products. All of that is driven by the many advantages of 3D printing, including:

- a quick launch of manufacturing complex parts or unique products in small quantities

- ability to develop 3D models in one place and send them in seconds to another site that has a suitable printer

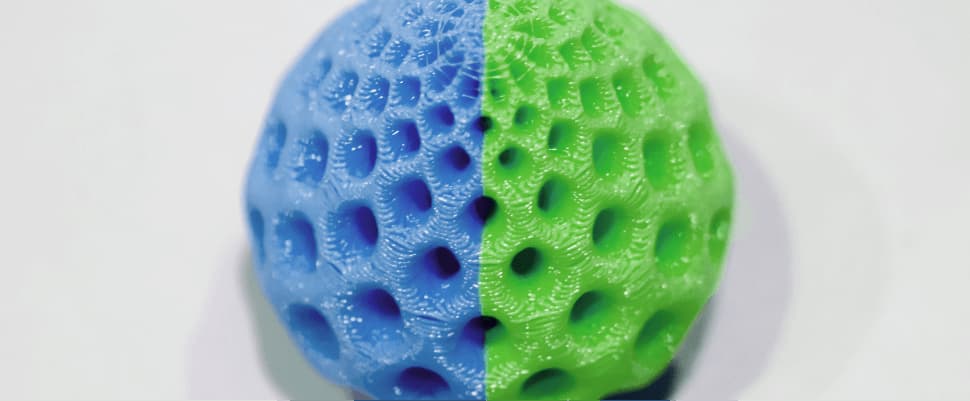

- high-quality printing ensures that a product exactly matches the 3D model

- low material consumption and waste minimization

- cost-effectiveness for small-scale production

- any time you need a part, you can print it

- making quick changes to a project even at the production stage

- easy to modify structural elements without affecting the durability of an object

- printing prefabricated units, which enables you to quickly and easily produce large-scale objects

In the future, additive technologies will continue to evolve. People will increasingly use them over traditional production methods to manufacture finished products.

Not being niche anymore, 3D printing has already evolved into a widespread and affordable technology. Infomir follows the most recent trends of additive manufacturing. We implement new technologies and make 3D printing available to our customers. Sign up for our newsletter to enjoy the latest news about additive manufacturing!