HP MJF vs. SLS: Comparing 3D Printing Technologies

Since its invention in the mid-1980s, the realm of 3D printing has seen remarkable advancements, with numerous technologies arising to address diverse manufacturing challenges. Among the foremost 3D printing technologies are HP’s Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS). These two methods present distinctive advantages and applications, yet they diverge significantly in terms of operational principles, materials, and final outcomes. In this article, we’ll delve into the workings of these technologies, highlight their fundamental differences, and explore the industries in which they are popular.

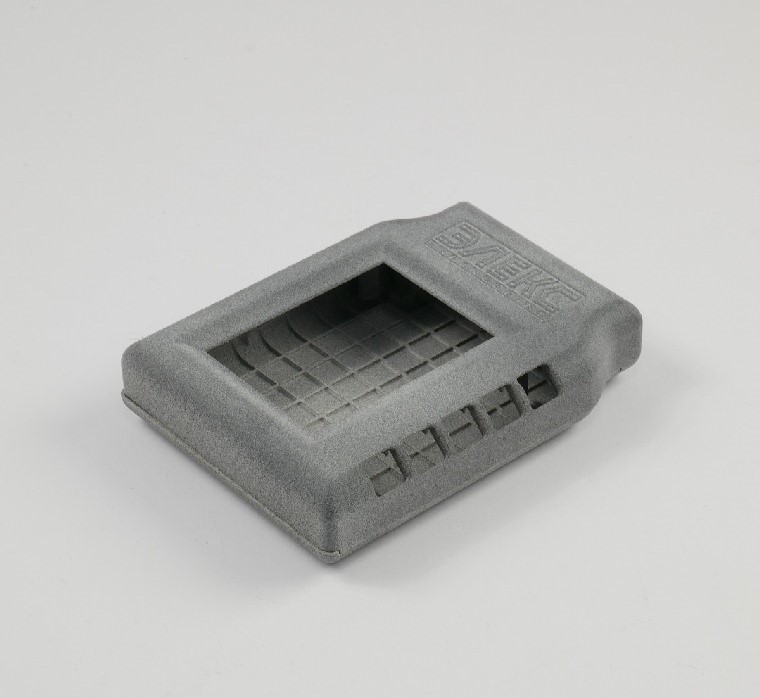

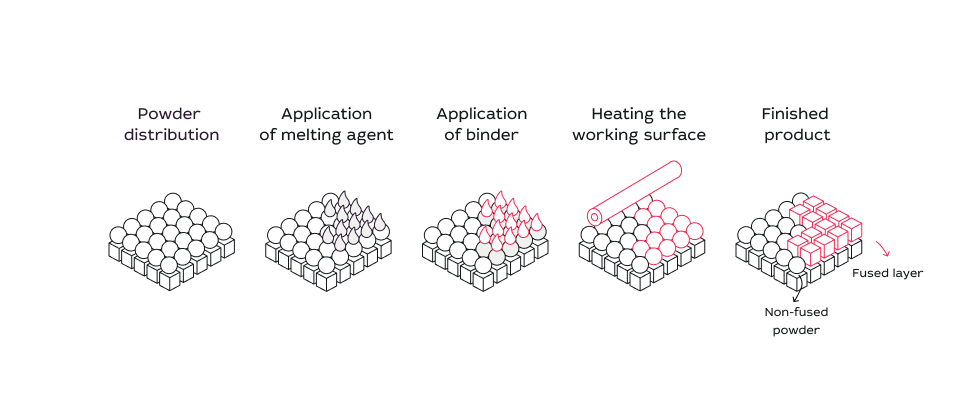

HP Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF), a relatively recent addition to the 3D printing landscape, has swiftly gained popularity thanks to its exceptional speed, precision, and versatility. Hewlett Packard pioneered this method, harnessing inkjet printing technology to construct components layer by layer in the production process.

The process kicks off by spreading a thin layer of powdered material onto the work platform. After that, the inkjet printing system applies the binder and melting agent onto the powder in a precise pattern. A heating element then goes over the bed, melting the powdered material and turning it into a solid structure. This process is repeated for each layer until the final 3D object is ready.

Advantages of HP Multi Jet Fusion

Speed: HP MJF outpaces many other 3D printing technologies, producing intricate parts swiftly. This makes it an ideal choice for rapid prototyping and high-volume production.

High resolution: MJF employs an inkjet-based approach, enabling the creation of parts with exceptionally smooth surfaces and intricate details, with capabilities reaching up to 1200 DPI and a layer thickness of 80 microns. This versatility makes the MJF working mechanism suitable for crafting products with small components and complex geometric shapes, including nested parts, interlocking structures, and hollow shapes – all without the need for support structures.

Variety of materials: With MJF technology, you can print parts using a wide array of materials. MJF 3D printing materials include nylon, polypropylene, and polyurethane, each offering distinct physical and chemical properties. This diversity allows for 3D printing applications across a spectrum of product purposes.

Post-processing: MJF-produced parts usually demand minimal post-processing, such as grinding or finishing, thanks to the excellent surface quality achieved during printing. In many cases, the parts are ready for use or may only require a simple sandblasting to meet the desired specifications.

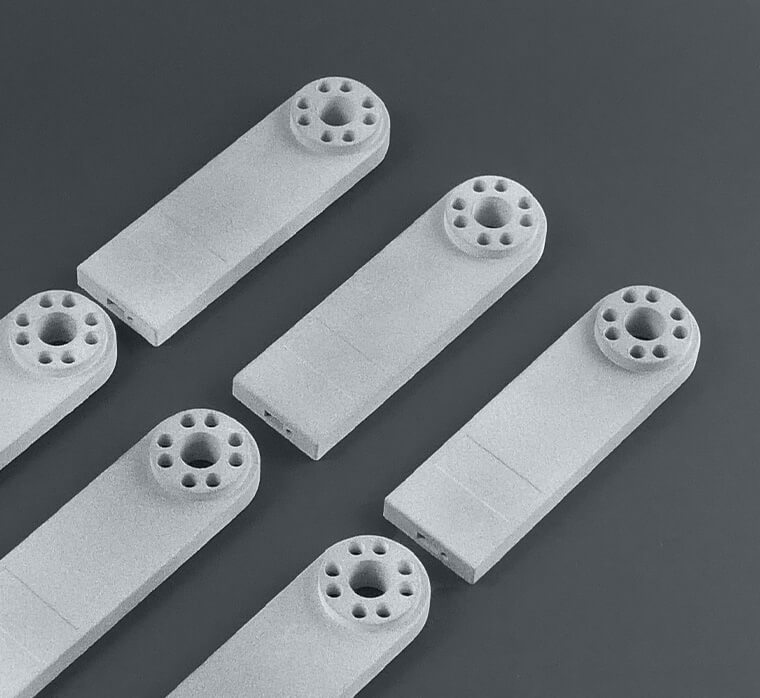

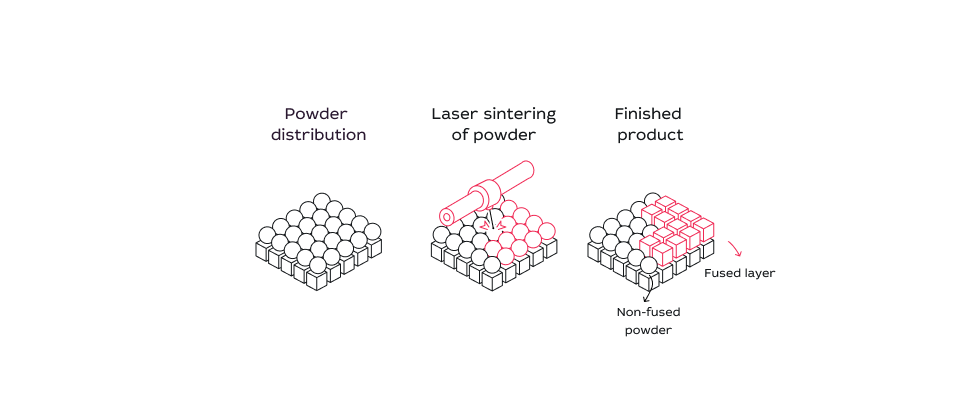

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) has been a stalwart in 3D printing technology for decades, maintaining its widespread usage. The SLS working principle is the sintering of powdered polymers by using a high-powered laser.

The fusing process starts by uniformly distributing a layer of powdered material across the work platform. Once completed and guided by the 3D model, the laser selectively sinters the powder particles together. This meticulous layer-by-layer process continues until the finished product is ready.

Advantages of SLS

Material versatility: SLS stands out as a versatile 3D printing method, offering a wide range of production materials. It accommodates an extensive number of thermoplastic powders, including various technical-grade polymers.

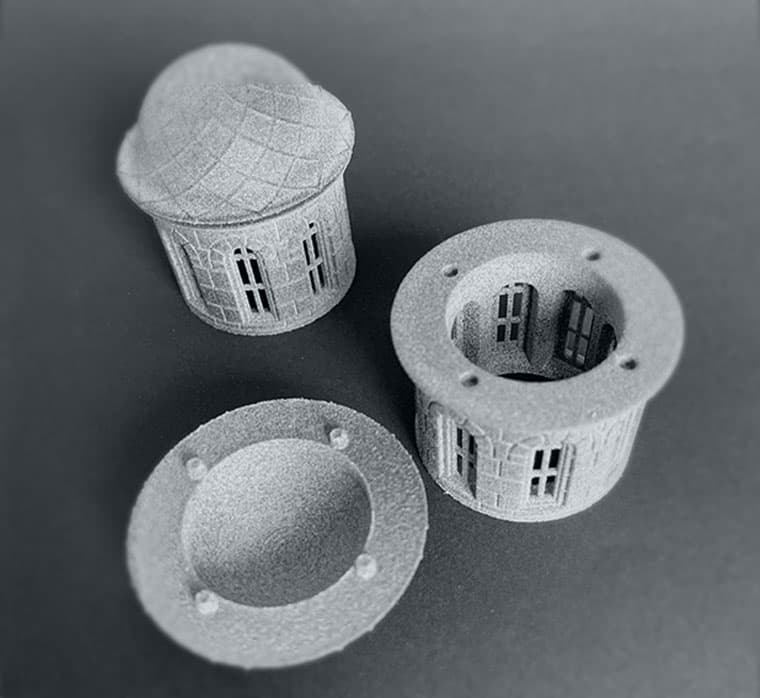

No supporting structures: In contrast to certain other 3D printing techniques, such as Fused Deposition Modeling (FDM), SLS operates without the need for support structures. This is achieved by employing the non-sintered powder as its own support during the printing process, negating the necessity for removing supporting components during post-processing.

Mechanical properties: Products crafted using SLS offer exceptional mechanical properties, making them suitable for the creation of functional prototypes and end-use parts. These products boast durability and resistance to high temperatures.

Complex geometries: The applications of SLS technology include the capability to fabricate parts with intricate and complex geometries. SLS dimensional accuracy means that it is considered to be a valuable technique in industries where design freedom holds paramount importance.

Key differences between MJF and SLS

Operating principle: The core distinction between HP MJF and SLS lies in how they work. HP MJF uses inkjet printing technology and a blend of binders and melting agents to make parts, while SLS employs a high-power laser to selectively sinter powdered materials.

Materials: Both technologies show flexibility in material usage, albeit with differing options. MJF supports printing across a diverse range of materials, even offering full-color capabilities, whereas SLS primarily focuses on powdered thermoplastics.

Speed: MJF boasts faster product printing compared to SLS, making HP’s technology the recommended choice for industries where rapid production is pivotal.

Surface finish: MJF yields products with smoother surfaces, reducing the necessity for extensive post-processing.

Cost: Pricing varies based on factors such as material selection and project-specific goals. MJF typically requires substantial investments for procuring an industrial printing line and related equipment. However, it offsets this cost with advantages in printing speed and diminished post-processing requirements.

Opting for the right technology for your project

The choice between MJF and SLS hinges on the specific project requirements. Let’s delve into several key considerations to keep in mind when selecting a printing technology:

Project complexity: When a project demands the creation of parts with intricate geometries or high levels of detail, MJF emerges as the optimal choice thanks to its inherent technological capabilities.

Speed vs. cost: If the goal is to rapidly produce reliable and durable products, with cost being a secondary concern, MJF is the preferred option. SLS printing, on the other hand, may offer cost savings but typically requires more time.

Materials: When your goals are all about material flexibility, MJF technology shines. Depending on the choice of powder, you can make products with diverse physical and chemical properties. For instance, it’s possible to print two identical parts but with varying degrees of elasticity or rigidity.

Post-processing: If you are looking to minimize post-processing requirements, MJF can significantly reduce the need for additional finishing work.

Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) represent innovative 3D printing technologies, each with its unique advantages and applications. When selecting the appropriate printing technology, it’s crucial to align the choice with the precise demands of the project. Key factors to consider include the complexity of the product, material specifications, printing speed, and cost considerations.