Up to 2 g: 1,000 architectural model parts

-

Client’s website:

-

Models:

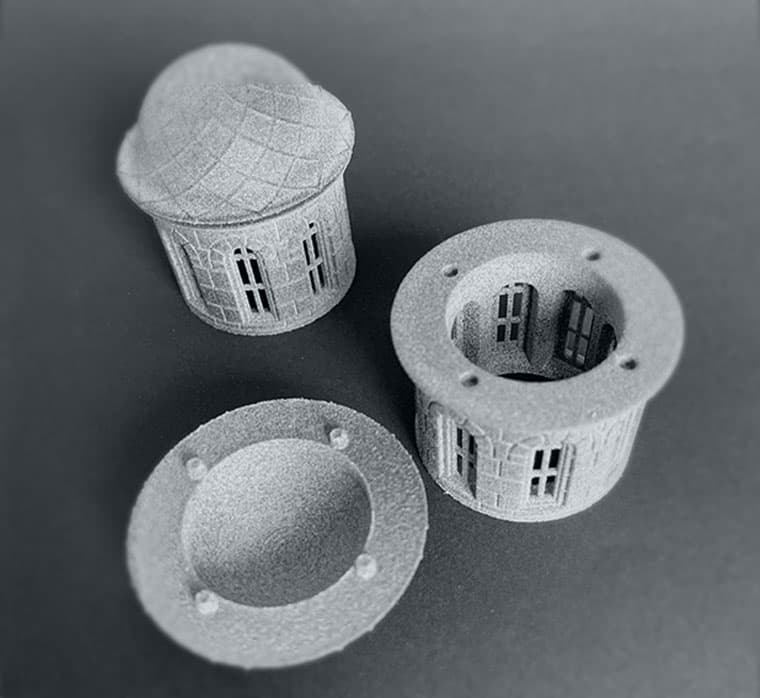

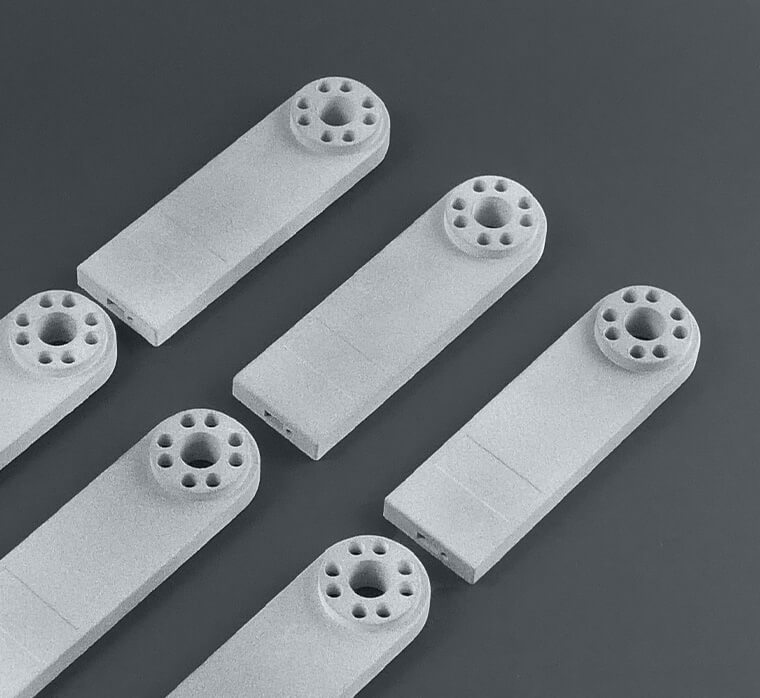

cupolas, fences, and bells for architectural models

-

Weight:

0.1–2 g

-

Quantity:

1,000 pieces

Arch Model Outlook is a Kyiv-based studio creating architectural models and building miniatures from polyamide, PVC, wood, metal, and cardboard. Real estate developers, museums, building restoration companies, and architectural miniature parks order its models. The studio often creates them for cathedrals and governmental buildings, with sizes varying from tens of centimeters to several meters. Every model has thousands of elements, and the level of detail of each determines its accuracy.

Client’s problem

Small elements are challenging to manufacture by hand. For example, even though a cupola or a part of a fence may weigh only 0.1–2 g, they are complex elements with railings, patterns, or a brickwork texture. The client’s studio tried to print them on an FDM printer was unable to achieve the required precision. Within five days, it needed to print 1,000 finely detailed small parts. Even industrial SLS printers could not pull this off.

Solution

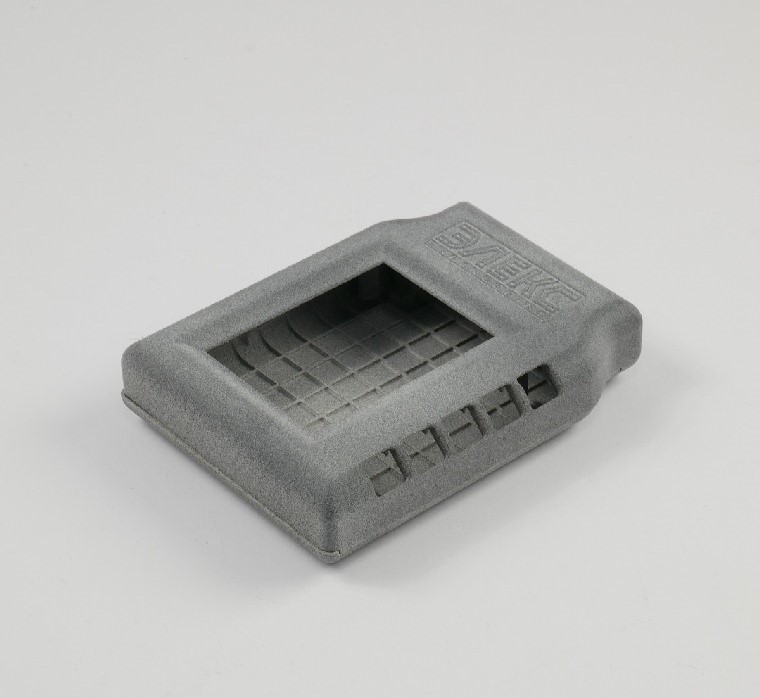

Arch Model Outlook placed an order with Infomir 3D Printing to make sure it could get the parts and have architectural models manufactured on time. We provided the required printing speed and level of detail—HP Jet Fusion 5210 prints with a hairbreadth layer thickness (80 microns) at 1,200 DPI. The source material is HP PA 12 polyamide powder. Once printed, the items were sanded to remove the remaining powder, taking care to avoid damaging the fragile parts like window frames, railings, and pointed elements. Within five days, we had printed, sanded, and shipped 1,000 pieces weighing 0.1–2 g to our client.

Result

We delivered architectural model parts to Arch Model Outlook on time to the required level of detail. Those elements have already become parts of miniatures. The studio saved several weeks production time, as it did not need to order Multi Jet Fusion printing from abroad.