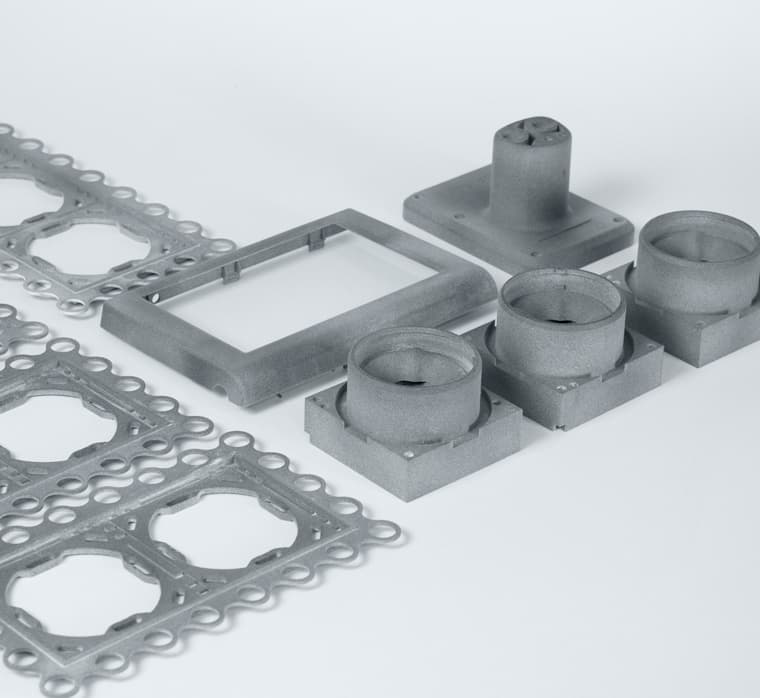

Socket cases for a 3D printing studio

-

Model:

socket case

-

Weight:

30 g

-

Dimensions:

7.75 x 112 x 254 mm

Client’s problem

A 3D printing studio began designing a socket case. The item had to be durable and wear‑resistant. The case required a temperature-resistant and insulating material. The designers had tried using FDM printing technology, but the quality didn’t meet the required technical specifications. As an alternative, they had poured plastic into molds, but it turned out to be time-consuming and expensive – some of the items required reworking and that meant having to order new molds.

Solution

The client turned to Infomir 3D Printing to get the items printed using the HP Jet Fusion 5210 industrial 3D printing line. The printer uses MJF technology and HP PA 12 polyamide. This material is innovative and enables us to make durable items that are resistant to ultraviolet, moisture, and chemicals.

Result

Infomir 3D Printing completed the order within four days. The items had a resolution of 1,200 DPI and a layer thickness of 80 microns. All socket cases complied with the technical specifications and required no additional processing. The client was delighted. MJF printing technology helped the studio get the right quality, save time, and cut costs.