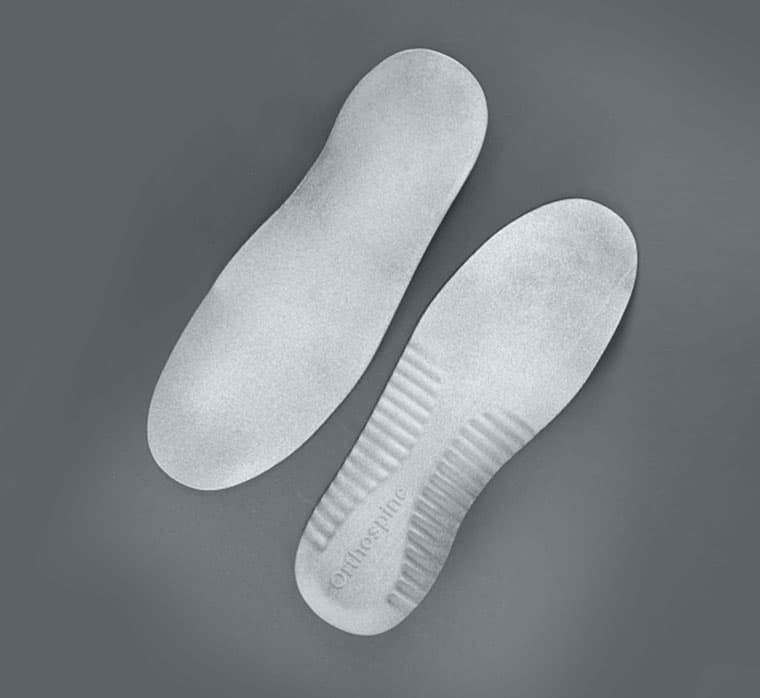

Orthotics for 3D Service studio

-

Client’s website:

-

Model:

orthotics

-

Weight:

45 g

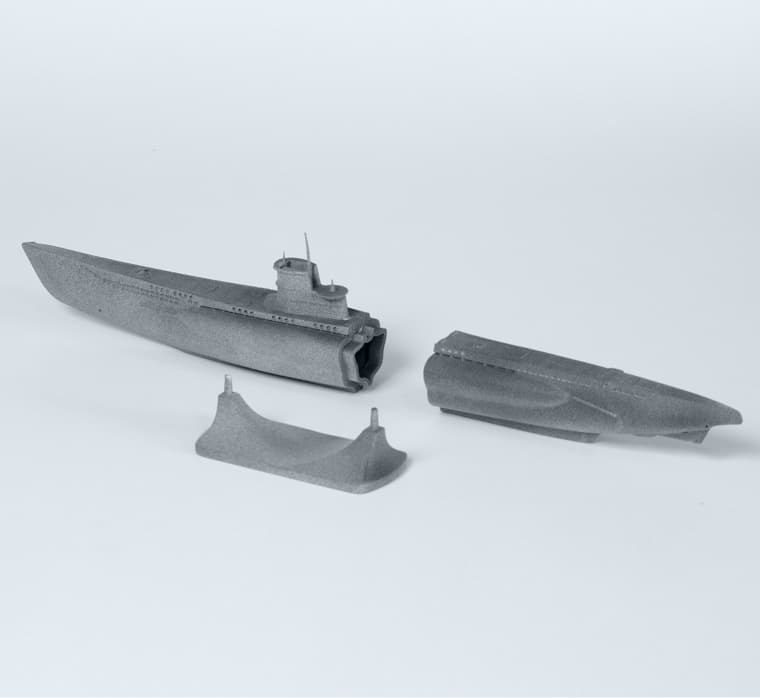

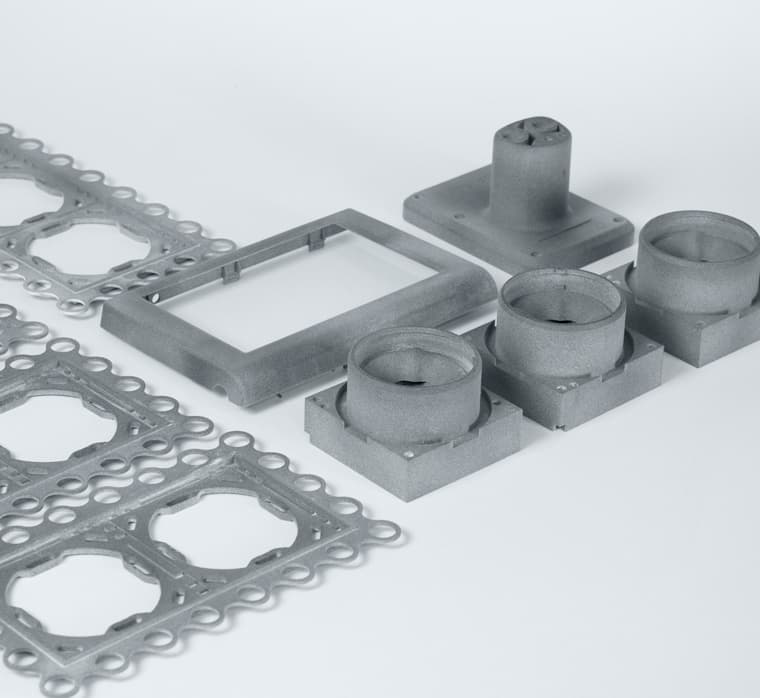

3D Service studio provides 3D printing, 3D scanning, and modeling services. The studio uses FDM, SLS, SLA, and MJM printing technologies, as well as molding plastics in silicon molds. The models are intended for automotive, medicine, jewelry, and scientific applications.

Client’s problem

3D Service got an order for size 41 (US size 9) orthotics. The product had to be elastic and resistant to constant mechanical load. The orthotics had to match the shoe precisely, limiting the printing error margin to 0.5 mm. Molding orthotics proved to be costly, while FDM printing didn’t provide adequate strength and durability.

Solution

The speed of MJF printing made it possible to print, sand, and ship the order within four days.

3D Service got light (45 g) orthotics that could bear human weight and didn’t need finishing.

Result

The client didn’t need to spend extra on orthotics. It takes orthopedic and foot health centers three times longer to manufacture a product like this, while shops sell it at twice as high a price.