A tool for unscrewing flasks and caps of home water filters

-

Client:

-

Model:

A tool for unscrewing flasks and caps of home water filters

-

Weight:

460 g

Ecosoft designs and manufactures water treatment equipment for domestic, commercial, and industrial use.

Client’s problem

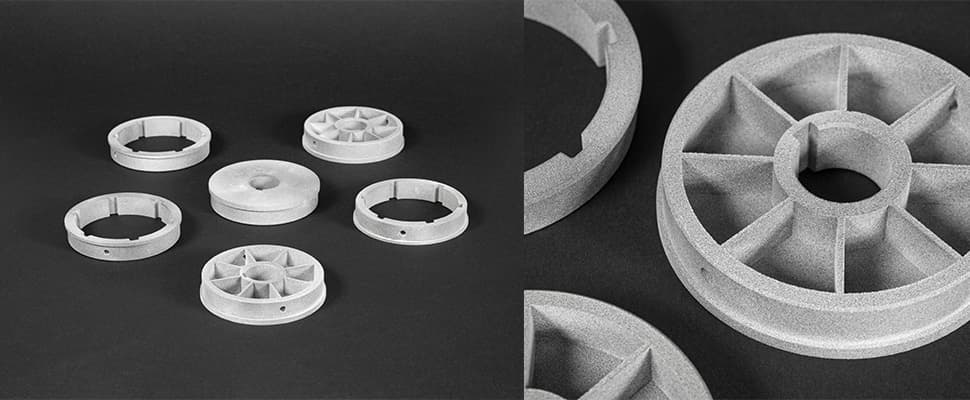

To test the design and performance of its products before casting, the company needed a set of parts for prototyping, i.e., mandrels for unscrewing flasks and caps of home water filters. We made six parts with a total weight of 460 g.

While the problem could have been solved mechanically, creating the parts would be prohibitively expensive. Besides, the client already tried printing them using a conventional 3D printer, but the quality was poor.

Solution

Ecosoft’s team turned to Infomir 3D Printing for help getting a set of parts printed on the Hewlett Packard Jet Fusion 5210 industrial 3D printing line. The printer uses HP PA 12 polyamide as a printing material, enabling us to make durable, lightweight items that are moisture, UV radiation, and chemical resistant.

Results

We printed and delivered a set of parts to the client within five business days. The items fully met the terms of reference. Thanks to Infomir 3D Printing, the client received high-quality components fast and at an affordable price.